The position of the strobes is variable according to the configuration of use and the number of units.

We can use a single strobe positioned on top of the housing for the macro close up, as well as a double unit supported and oriented by arms for wide angle photography.

With this latter setting the strobes will be rotated by 180° making it difficult to read the control display in the upside down position.

The simultaneous operation of the left and right lever selectors for a given time allows the numerical indication of the central display to be inverted, making it possible to read always easily the selected values of power or compensation, regardless of the flash position.

The execution of this command is combined with the emission of a low-power flash, useful for quickly checking the operation of the strobe even without digital camera connected.

The sensitivity we have in operating a control in air is lost or strongly attenuated in water due to the very nature of the element.

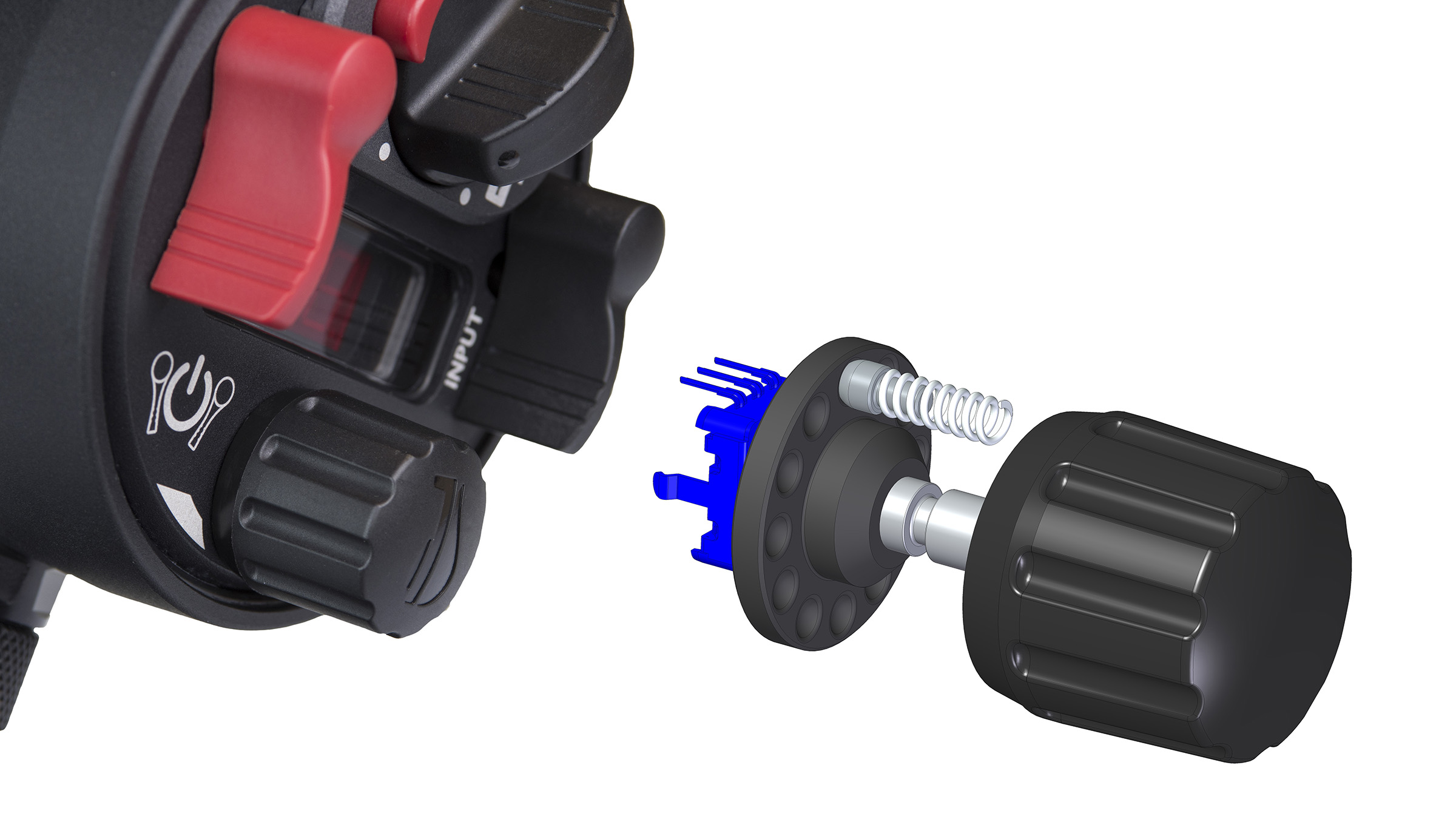

The central rotary control has been given the correct sensitivity, even with the use of gloves, replicating and amplifying the encoder’s proprietary shots by means of a divider disk with tip marking position.

The components are made of hard anodized teflon-coated aluminum and anti-friction technical polymer.

The rotation of the control is thus fluid, precise and with the right “click” to each position.

An important element for the safety of the system.

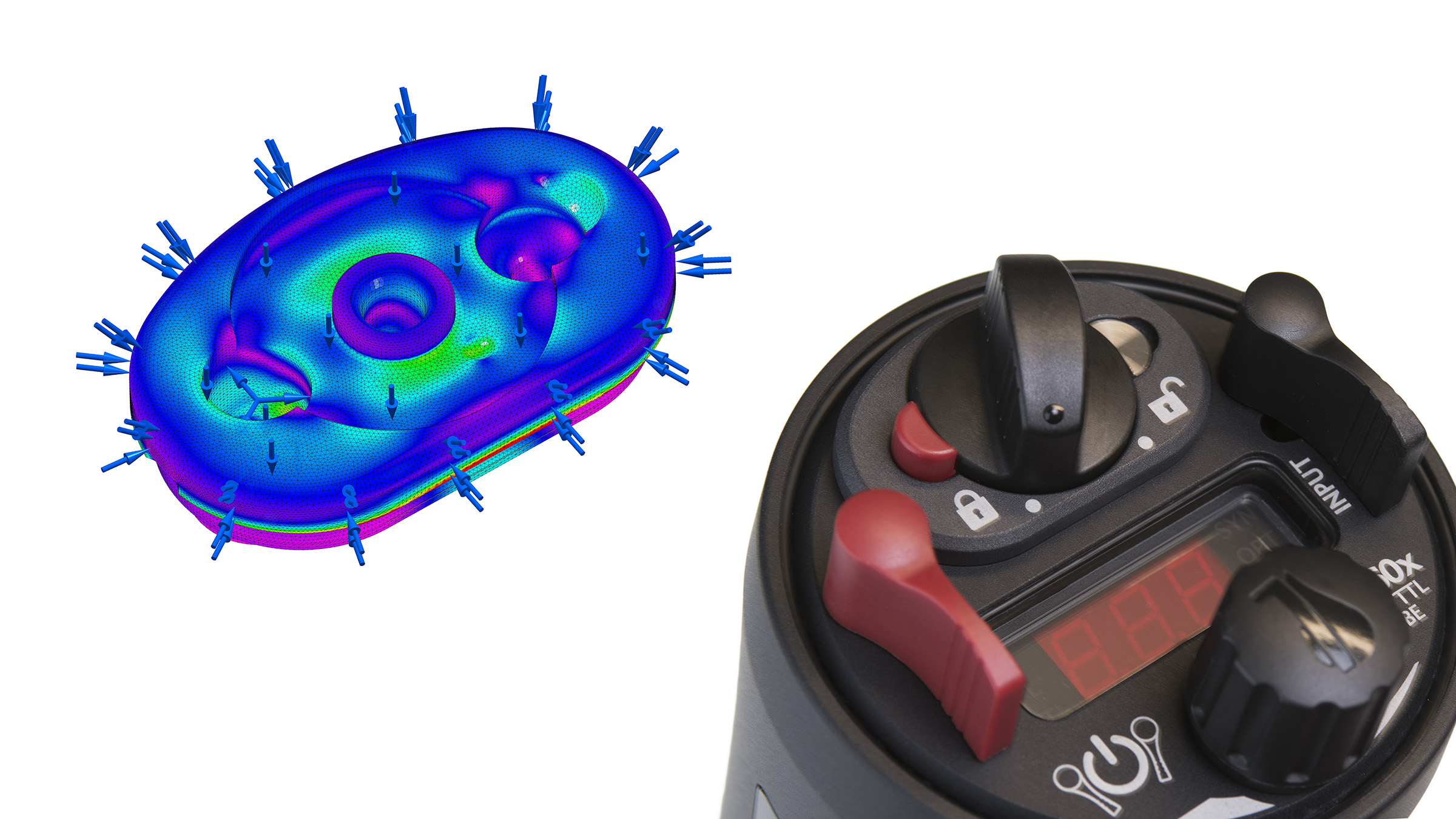

The body, seat of the sealing o-ring, is made of high-quality anticorodal aluminium protected by a hard anodizing treatment, the locking shaft is made of stainless steel.

The structural strength and deformation of the component, such as the verification of the specific pressure of the couplings, were calculated and analyzed by FEM simulations.

The opening is easy thanks to the ergonomic selector, made of molded technical polymer, equipped with safety release and locking in the open position.

Operational safety, in the event of any malfunction of the battery pack that generates dangerous gas inside the battery compartment, is guaranteed by the presence of a special over-pressure rilef valve made of stainless steel.

No compromise for your safety.

In TTL mode, the amount of light is dosed automatically.

Knowing how much is the strobe output energy in case you want to take additional shots by varying the aperture or shutter speed is useful and valuable information.

For this reason, after every shot in TTL mode, the display shows the percentage of power output supplied by the strobe.

in this way it is possible to vary the exposure parameters in the right way, always ensuring full power coverage of the strobe.